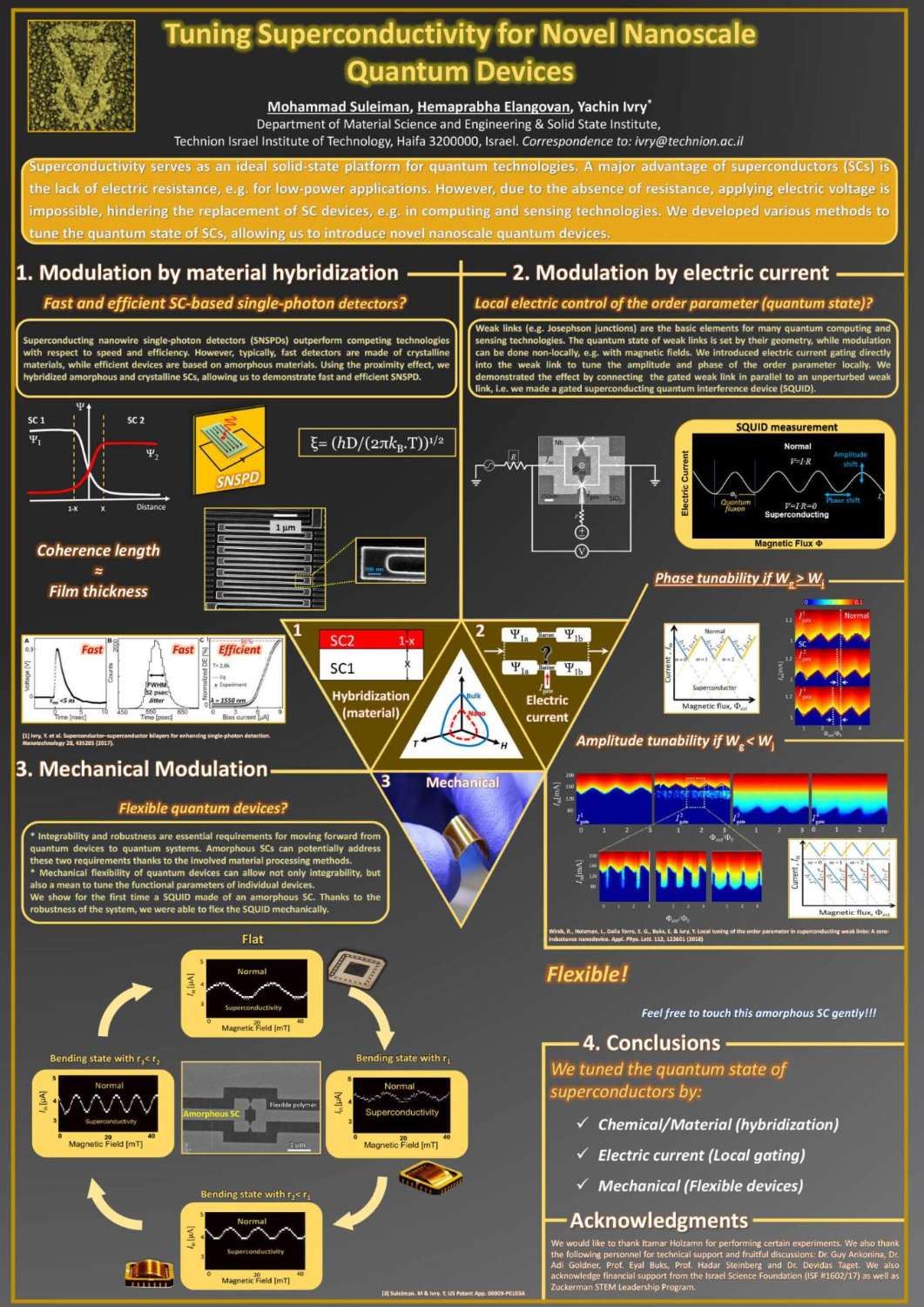

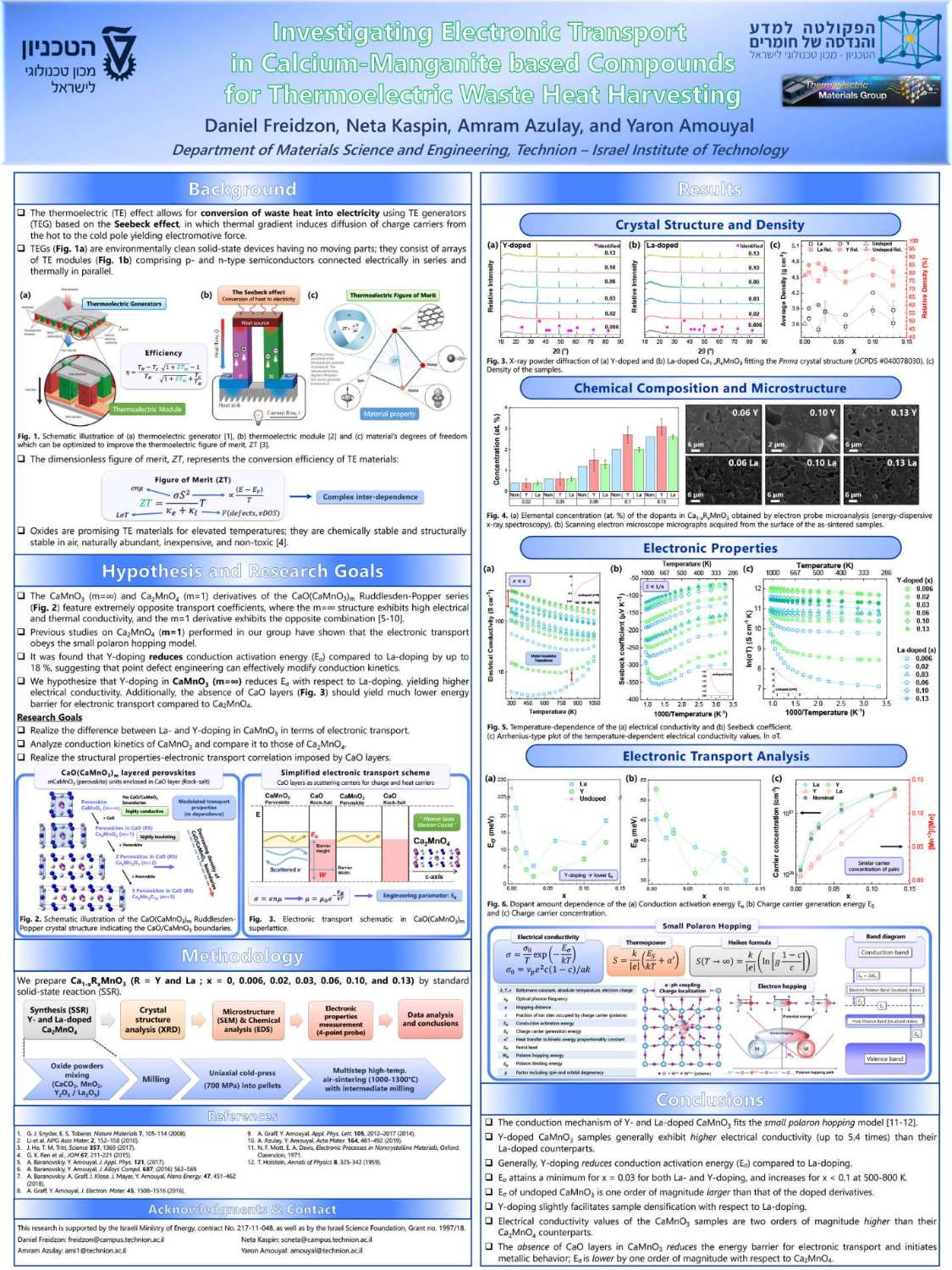

Department of Materials Science and Engineering

The mission of the Department of Materials Science and Engineering is to serve as the national center of teaching and research in materials science and engineering, by educating world class scientists and engineers and conducting cutting edge research in specific fields of materials science and engineering.