Specimen Preparation

| Gatan 656 Dimple Grinder | Buehler MiniMet 1000 – semiautomatic grinder/golisher | Buehler IsoMet Low Speed Saw – precision sectioning saw | Buehler EcoMet 3000 – variable speed grinder/polishers |

|

|

|

|

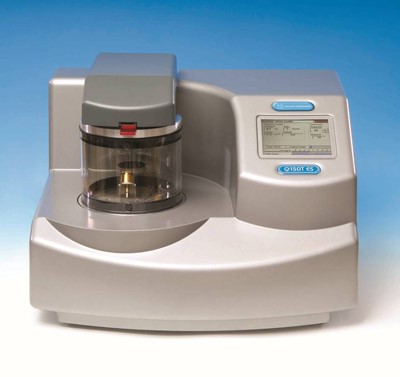

Gold & Carbon Coating

Q150T Turbo-Pumped Sputter Coater/Carbon Coater (Quorum Technologies Ltd.)

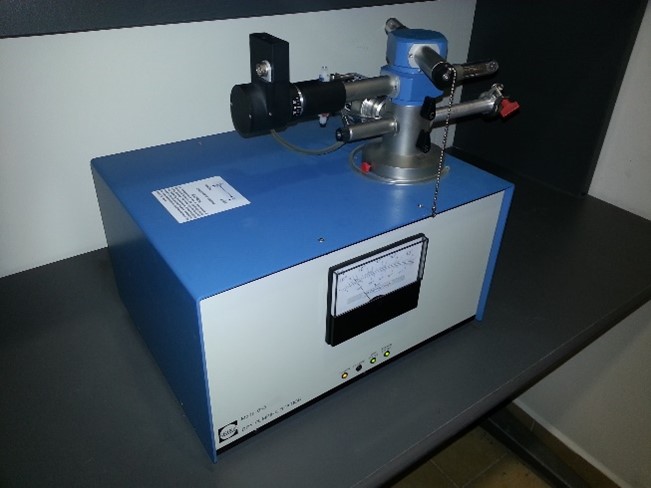

Polaron gold coater

Polaron carbon coater

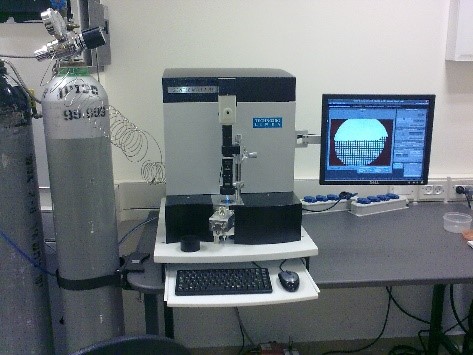

Gentle Mill

IV8 Gentle Mill (Technoorg Linda Ltd., Hungary).

Plasma Cleaner

Fischione plasma cleaner – model 1020

Dry Pumping Station

Gatan 655 Dry Pumping Station

Microtome

Reichert-Yung Ultracut E

PIPS-II

Gatan 695 Precision Ion Polishing System (PIPS-II)

Electropolisher

Struers Tenupol-5 Electropolisher.

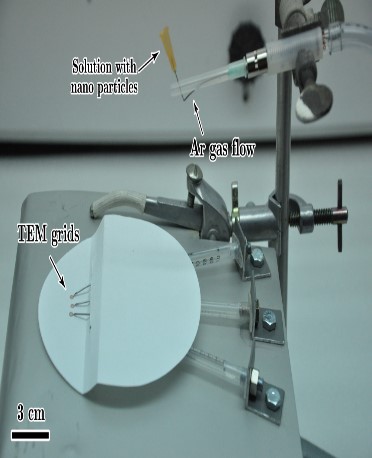

Spray Deposition

An apparatus for the preparation of nano-particles which avoids agglomeration of the particles and dramatically reduces the contamination rate, and therefore enables reliable analysis of such particles. The method is based on spraying the volatile solution containing the nano-particles onto the supporting film using a disposable and fairly simple homemade and disposable apparatus which was developed in our laboratory.

A few droplets from the volatile solution containing the nano-particles are dropped into the top needle and sprayed using the pure Ar gas flow from the horizontal needle producing a very fine slurry which lands on the thin film coated TEM grids.

Typical conditions for gas flow:

- Gas pressure – 0.5 atmospheres.

- Flow rate – 2 liters/minute.