The development by Technion researchers is expected to accelerate, streamline, and reduce the cost of industrial polymer production processes

Researchers from two Technion faculties present a new strategy for measuring mechanical forces in biological processes. The research, published in the Journal of the American Chemical Society, was led by Assistant Professor Joshua Grolman and Yifan Liao from the Faculty of Materials Science and Engineering in collaboration with Associate Professor Charles Diesendruck from the Schulich Faculty of Chemistry.

Mechanobiology is a field of research that deals with the influence of mechanical forces on various biological processes. Measuring these forces at the molecular level is a complex challenge, and the development by Technion researchers is expected to enable measurements that were previously impossible.

L to R: Assistant Professor Joshua Grolman , Yifan Liao and Associate Professor Charles Diesendruck

Various mechanobiological systems, which have evolved over immense periods, demonstrate high efficiency in “translating” mechanical forces into biological signals. These natural systems provide significant inspiration for engineering developments. However, it is very difficult to replicate their level of precision in artificial systems, especially at the molecular level. Therefore, breakthroughs in this field are crucial in many contexts, including drug delivery within the body, monitoring defects in materials and developing self-repairing materials.

The technology developed at the Technion is based on mechanophores – molecular units that produce chemical or physical signals when subjected to structural changes such as pressure or stretching. Measuring these signals, which provide information about the state of the material, is a very complex technological challenge, especially when high sensitivity is required. The technology developed by the researchers is characterized by very high sensitivity compared to previous uses of mechanophores and responds even to a strain of just 5%, making it highly relevant for various biological processes that could not be monitored until now. This technique is relevant to a variety of biological and artificial materials.

Yifan Liao

Technion researchers succeeded in producing a force-sensitive material from a molecule called spiropyran, thereby creating a sort of molecular detector that provides information about the mechanical forces within the material. The required method is a click chemistry process, meaning it does not require multi-step processes and is not associated with undesirable by-products.

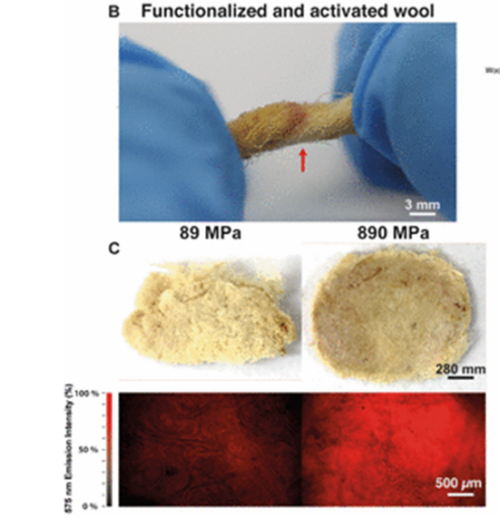

The new strategy, Dip-conjugation, is demonstrated in the article with an analysis of the wool fibers of the alpaca – an animal from the camel family, particularly common in South America. The advantage of this technology is that it is applicable to both synthetic and natural materials, including materials made from proteins and carbohydrates. The researchers estimate that in the industrial field, this technology will contribute to accelerating and reducing the cost of manufacturing mechanophores in polymers.

In addition to biological applications, the researchers mention that “the materials we have developed could turn many biological and artificial materials into sensors with exceptional sensitivity. They could also be used to coat aircraft components, providing alerts on emerging failures in these components.”

In the diagram: Measurement of biomechanical forces applied to alpaca wool in twisting (top) and compression (bottom) states.

The research is supported by the Israel Cancer Research Fund (ICRF) and the Israel Science Foundation (ISF).

For the full article in Journal of the American Chemical Society click here